Concrete Test Cylinders

Did you know that Jatco also owns and runs one of the highest quality concrete cylinder mold companies? Since 1980, we have been the go-to company for concrete test cylinder molds in the United States. Companies that are looking for concrete test cylinders have always turned to JATCO and we invite you to take a look at our online catalog where you can see a large variety of our concrete products, very competitive prices, and learn how we can help your company out. We offer numerous sizes and colors of concrete test cylinders and you can even get your company’s logo and information stamped on them.

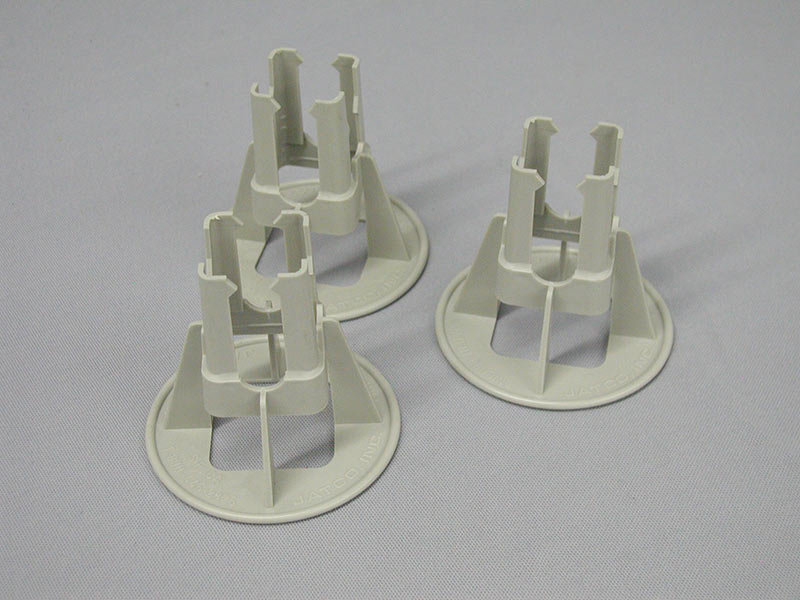

CORNER GUARDS – Our Corner Guards are manufactured in two sizes: 1 3/4″ and 4 1/4″ widths. Safety is a key consideration because using the right equipment helps to make certain that your products arrive at the job site in one piece. This can include using a secure load tie-down system and tensioning straps to help protect against impact or lateral load from bumps in transit. This product may be used in other tie down applications for lumber, masonry, sheet rock, paper products or any other palletizing or stackable material that needs to be secured for storage, moving, or shipping.

PANEL PADS – Our Panel Pads can be used flat or folded double to create a larger separation between your precast concrete products during storage and shipping. Concrete chips, fractures and tipping can be eliminated with this panel pads. Panel Pad dimensions are 6 1/2″ x 2 1/2″. Our plastic Panel Pads can also be used to protect rock, stone, architectural facades or any finished surface.

If you’re new to the concrete test cylinders industry then read below and discover the intricacies of concrete test cylinder molds, diverse applications, and the role they play in ensuring concrete compressive strength and quality.

Concrete test cylinders are fundamental in measuring the compressive strength of concrete, a critical factor in construction quality assurance. These cylinders, typically made through plastic injection molding, offer a standardized method for evaluating concrete strength, ensuring that structures meet safety and durability standards.

Cylinder test molds are indispensable in creating uniform and accurate concrete test cylinders. Made from high-quality materials, these molds ensure consistency in testing, which is crucial for reliable strength assessments. Cylinder mold materials are selected for their durability and ability to produce precise concrete samples.

Adherence to ASTM (American Society for Testing and Materials) standards is crucial in concrete testing. ASTM concrete testing guidelines provide a framework for accurately assessing the compressive strength of concrete, ensuring that the concrete used in construction projects is of the highest quality and safety standards.

Our concrete test cylinders and molds are designed in strict compliance with ASTM and AASHTO standards. This compliance is not just a regulatory requirement but a commitment to quality and safety in the construction industry.

Concrete cylinder compression testing is a critical process in determining the strength of concrete. This testing involves placing concrete samples in cylinder molds and subjecting them to compression until failure, thus determining the material’s strength.

Making concrete cylinders involves precise steps to ensure the accuracy of test results. This process requires careful attention to the mixture, mold filling, and curing of the concrete samples. For decades we have been manufacturing and shipping concrete cylinders to customers all over North America and can help you with your needs.

In addition to cylinder molds, we provide a range of concrete testing accessories designed to enhance the testing process’s efficiency and accuracy. These accessories are crafted to meet the diverse needs of the construction industry.

Customers all over the U.S. select our concrete mold materials for their durability and performance, ensuring long-lasting use and consistent results. This durability is a key factor in providing reliable and accurate concrete testing solutions.

Concrete cylinder applications extend beyond basic strength testing. They are also used in research, quality control, and educational settings, providing valuable insights into concrete behavior under various conditions.

Q: What are concrete test cylinders used for?

A: Concrete test cylinders are used to test the compressive strength of concrete, ensuring it meets safety and quality standards.

Q: Are your cylinder molds ASTM compliant?

A: Yes, our cylinder molds meet all ASTM and AASHTO standards, ensuring reliable and standardized testing.

Q: Can the cylinder molds be customized?

A: Absolutely, we offer customization options, including different sizes, colors, and company logo stamping. Visit our site TestCylinder.com to learn more.

Q: What materials are used for cylinder molds?

A: Our molds are made from high-quality, durable materials, to ensure precise and consistent testing results.

Q: How do you ensure the accuracy of concrete testing?

A: We ensure accuracy by adhering to ASTM standards and providing high-quality, reliable testing equipment and accessories.

About Jatco

JATCO is a SF Bay Area plastics manufacturer who is knowns as a global leader in plastic injection molding. We are a one stop shop which offers plastics product (life) consulting, plastics design, plastics production, warehousing and distribution solutions for just about any project.

JATCO CONTACT INFORMATION

Our World Headquarters address is:

Jatco Incorporated

4801 Stoddard Road

Modesto, CA 95356 USA, U.S.A.

Tel: 209.497.4297

Fax: 510.4871880

Also visit our other sites (click below): TestCylinderMolds for test cylinders

Plantway for plant trays